What is the difference between a 2-stroke generator and a 4-stroke generator

Lead:

In today's power field, generator technology is changing rapidly. Among them, 2-stroke generators and 4-stroke generators are two common types, which have significant differences in structure and operation. Today, we will delve into the differences between these two types of generators in order to help readers better understand how they work and their advantages and disadvantages.The first thing to know is a concept: what is a stroke? When the piston moves back and forth in the cylinder, the process of moving from one end of the cylinder to the other end is called a stroke.The most direct difference between a 2-stroke generator and a 4-stroke generator is that the process of the two is different, and the 2-stroke only needs to run twice, and the 4-stroke needs to run twice more. The following details how they work, so that you can better understand.

A, 2 stroke generator

First of all, from the structural point of view, the two-stroke engine is relatively simple, mainly composed of cylinder head, cylinder, piston, piston ring and other parts, there is no complex valve mechanism and lubrication system, cooling system is generally air-cooled.

The two-stroke engine works as follows:

The first stroke: the piston moves upward from the bottom dead center, and after the three pores are closed at the same time, the mixture entering the cylinder is compressed; When the air intake is exposed, the combustible mixture flows into the crankcase.

Second stroke: When the piston is compressed near the top dead point, the spark plug ignites the combustible mixture, and the gas expands to push the piston downward to do work. At this time, the air intake is closed, and the combustible mixture sealed in the crankcase is compressed; When the piston is close to the bottom dead center, the exhaust hole opens and the exhaust gas rushes out; Then open the air exchange hole, the pre-loaded combustible mixture is injected into the cylinder to drive away the waste gas, and the air exchange process is carried out.

The operation of a 2-stroke generator is based on two key steps: suction and compression. Unlike conventional internal combustion engines, 2-stroke engines have no work and exhaust steps. Therefore, its structure is relatively simple, the operating cost is low, but the efficiency is relatively low. This type of generator works well in small equipment and small projects, but is not suitable for application scenarios that require a lot of power.

Two, 4 stroke generator

Four-stroke engines require more complex structures, including valve mechanisms and lubrication systems.

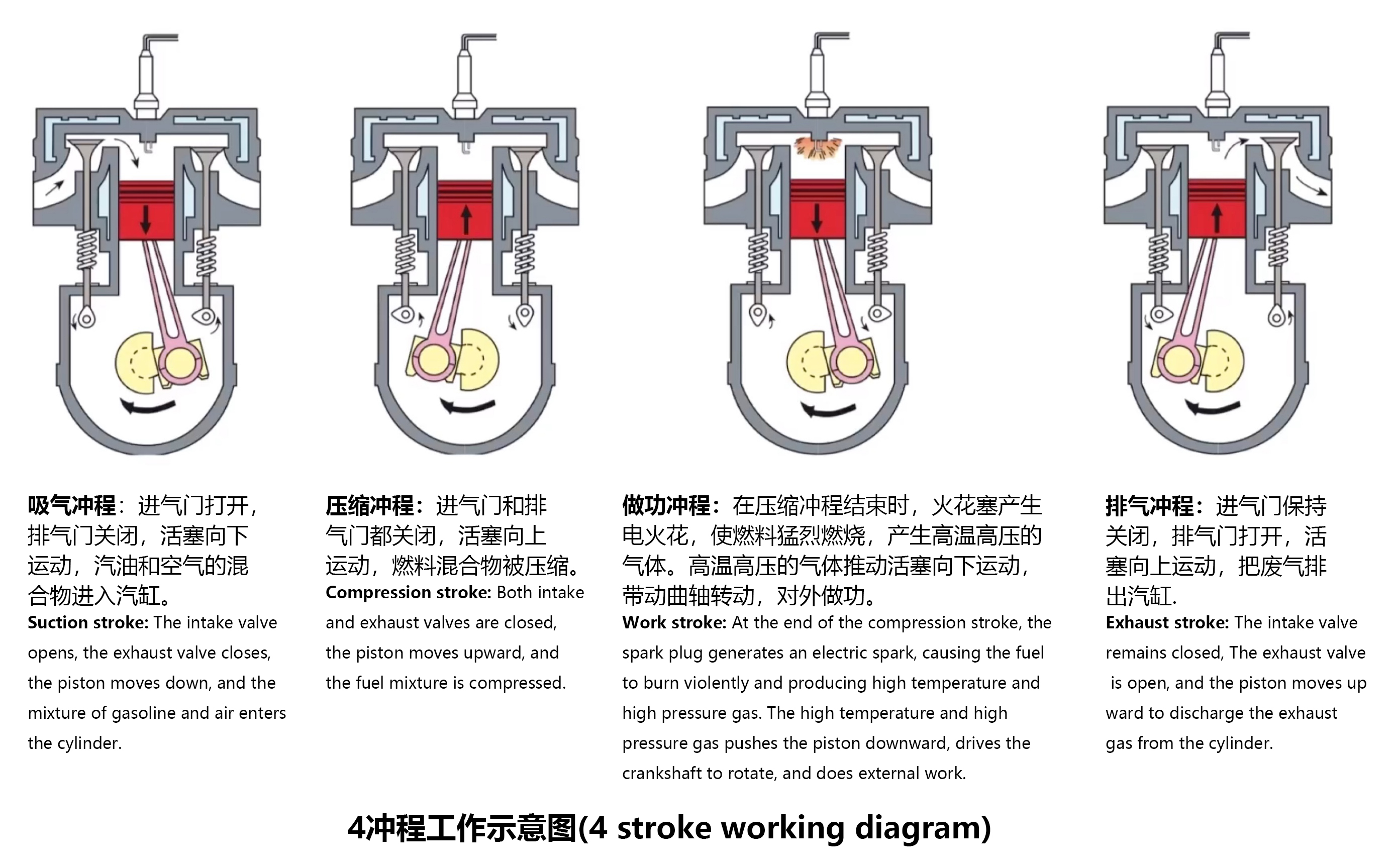

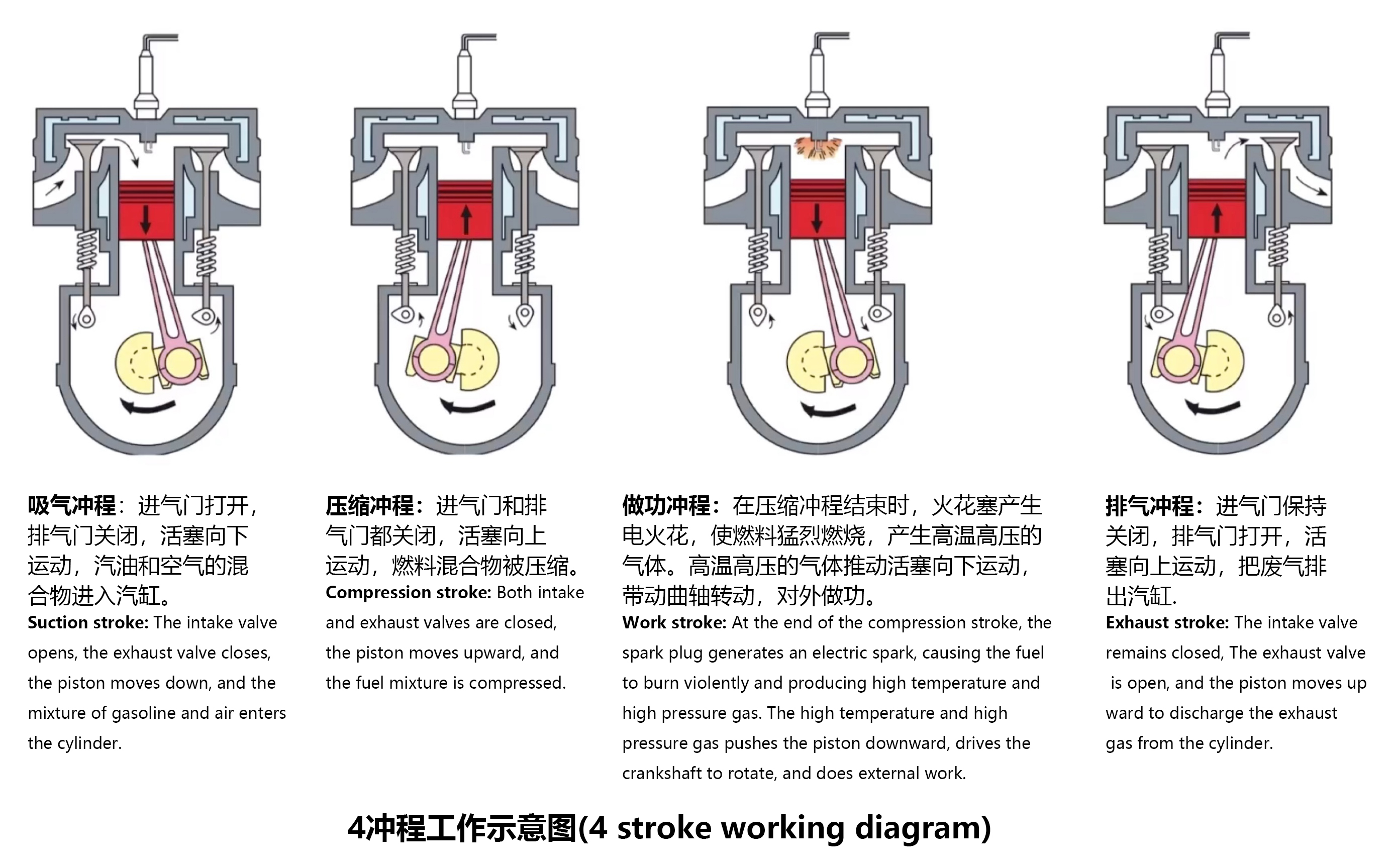

The four-stroke engine works as follows:

Suction stroke: The intake valve (L) opens, the piston moves downward, the mixture of fuel and air enters the cylinder, and the intake valve closes when the piston movement is minimal.

Compression stroke: the intake valve and exhaust valve are closed, the piston moves upward, the mixed gas of fuel and air is compressed, and when the piston moves to the top, the compression stroke ends, converting the mechanical energy into internal energy.

Work stroke: The spark ignites the gas mixture, and the burning gas expands rapidly, pushing the piston down and converting internal energy into mechanical energy.

Exhaust stroke: The exhaust valve (R) opens and the piston moves upward to discharge the exhaust gas after combustion. When the piston moves to the top, the exhaust valve is closed.

The working principle of the 4-stroke generator includes four steps of suction, compression, work and exhaust, which is the same as that of a conventional internal combustion engine.

Therefore, the main difference between 2-stroke generators and 4-stroke generators is that the structure is different, resulting in different working principles, and also causes their aspects to be diifferent .

1. Efficiency: Compared to 2-stroke generators,,4-stroke generators have higher efficiency and can convert fuel into electricity more efficiently.

2. Noise and vibration: Compared to 2-stroke generators,the 4-stroke generator produces less noise and vibration during operation, which is more in line with environmental protection requirements.

3. Application scenario: The 2-stroke generator is suitable for application scenarios with high requirements for volume and weight, while the 4-stroke generator is more suitable for various application scenarios with large power demand, such as industrial production and home power supply.

4. Maintenance cost: 2-stroke generator structure is relatively simple, low maintenance cost. 4-stroke generators require more frequent maintenance and calibration to keep them operating efficiently.

However, it is important to note that whether it is a 2-stroke or 4-stroke generator, their design and operation depends on the specific fuel (such as gasoline, diesel or natural gas, etc.) and environmental conditions (such as temperature, pressure, etc.). Therefore, in practical applications, we also need to select and adjust according to the specific situation.

Conclusion:

In general, 2-stroke generators and 4-stroke generators have their own advantages in design and operation. The 2-stroke generator is suitable for some specific application scenarios because of its compact, lightweight and low operating cost. 4-stroke generators have higher efficiency and lower maintenance costs, and are more suitable for scenarios that require large amounts of power. When choosing which type of generator to use, we should consider the performance of the equipment, maintenance costs, environmental factors and project needs.

In the future, as technology continues to advance, we expect to see more innovative generator designs to meet the power needs of different fields and scenarios.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Čeština

हिन्दी

فارسی

українська

Հայերեն

Dansk

বাংলা

Afrikaans

Gaeilge

Oʻzbekcha

Azərbaycan dili

Беларуская мова

Български

Galego

ქართული

Lietuvių